SR plastic filler

- Commodity name: SR plastic filler

Contact Info

Classification

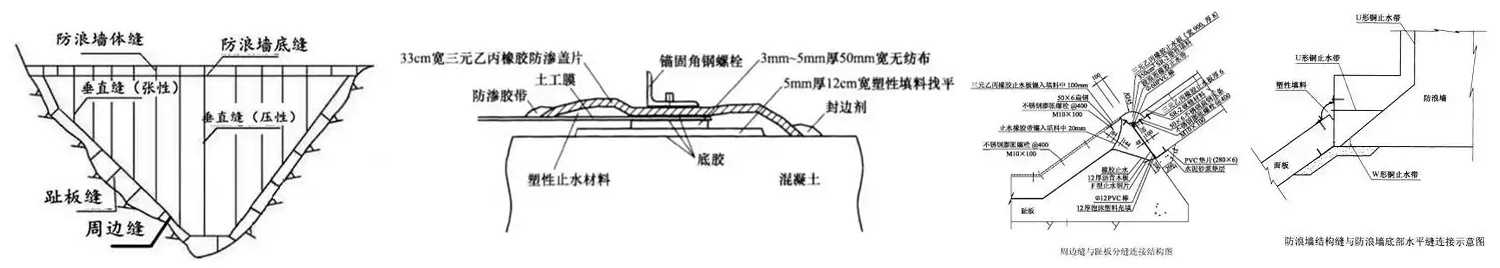

SR plastic waterstop material is a new type of caulking waterstop material. It is made by adding some SR-2 nano-material to the formula of SR plastic filler and GB flexible filler, improving the quality of SR plastic waterstop material. Therefore, it is also often called SR-2 plastic waterstop material. Its characteristics include high plasticity, good impermeability, good aging resistance, good high and low temperature resistance, and cold construction at normal temperature. It is the main waterproof material for the waterstop structure of the SR seepage prevention system in the peripheral and vertical seams of panel dams.

Application Scope

SR plastic waterstop material is mainly used as a caulking waterstop material in the construction of panel rockfill dams. For example: waterstop sealing in concrete panel joints, rockfill dam peripheral joints, wave-proof wall joints and bottom joints, vertical joints, and toe plate expansion joints.

Concrete Rockfill Dam Joints

Usage Scenarios

|

|

|

| Tunnels and Subways | Basements | Hydropower Dams |

About Us

Hengshui Guangyuan Waterstop Materials Technology Co., Ltd. is a comprehensive enterprise that has been committed to the research, development, production, and sales of engineering waterstop rubber for nearly 30 years. It specializes in the research, development, production, and sales of professional sealing waterstop materials: water-swelling waterstop strips series, single/double-component polyurethane sealant series, steel plate putty waterstop series, rubber waterstop series, and caulking clay series products. The products are reliable in quality and widely used, and have been recognized by many engineering units!

Business Philosophy: Focus on building waterproofing: Providing high-quality products and services for building waterproofing

Service Concept: To make customers satisfied with comprehensive, meticulous, and efficient service

Business Spirit: Quality Assurance, Professional Service: Double guarantee to eliminate the worries of users about waterproofing

Production and Inspection

Factory Photos

Keywords

Free Access To More Product Information

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible!