Steel plate putty waterstop

- Commodity name: Steel plate putty waterstop

Contact Info

Classification

The function of butyl mastic steel plate waterstop

Butyl mastic steel plate waterstop is a new type of waterstop material. It is a waterstop with a special structure. It is a composite waterstop made of galvanized steel plate wrapped in butyl rubber mastic, used as a waterproof sealing material for concrete construction joints. When using steel plate mastic waterstop, the steel plates on both sides have strong adhesion to the surrounding concrete structure, and the steel plate and rubber are firmly bonded. When the structure deforms, only the glue part is elongated and thinned, and no new leakage gaps will be generated between the steel plate and the concrete, and between the steel plate and the rubber. Therefore, the use of steel plate rubber waterstop enhances the waterproof effect when the structure deforms.

Butyl steel plate mastic rubber waterstops are mainly used in construction joints and deformation joints of major projects such as tunnels, subways, dams, culverts, water conservancy and hydropower projects, sedimentation tanks, reservoirs, water conveyance troughs, basements of high-rise buildings, and underground parking lots to ensure the service life of building projects.

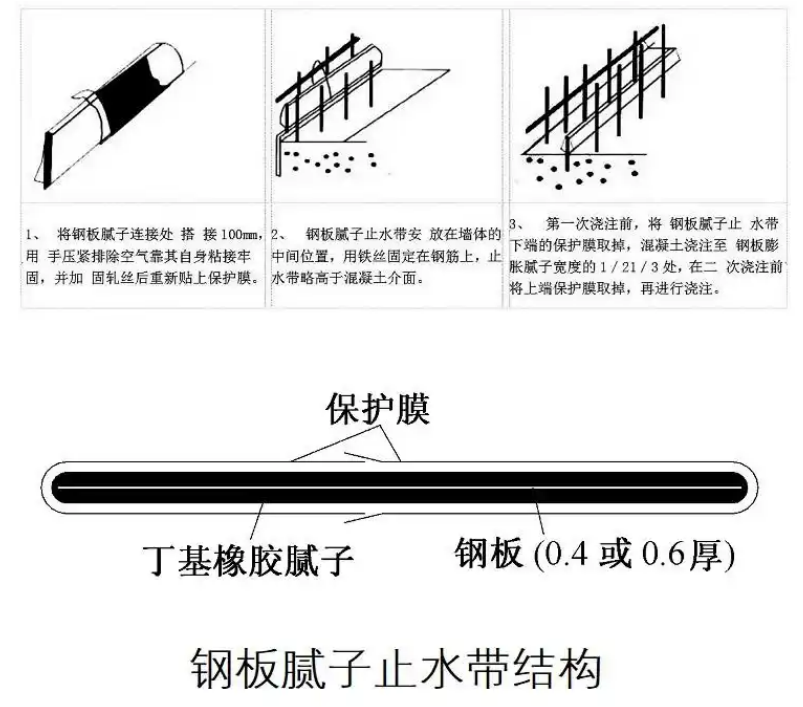

Construction methods of steel plate mastic waterstop

1. Joint lap: The steel plate mastic waterstop joints are overlapped by 100mm, pressed tightly by hand to remove air, relying on the self-adhesion of the steel plate mastic waterstop, and after reinforcing the wire, re-paste the protective film.

2. Fixed position: Place the steel plate mastic waterstop in the middle of the wall, and fix it to the reinforcement with wire, with the waterstop slightly higher than the concrete interface.

3. Pouring: Before pouring, remove the protective film at the bottom of the steel plate mastic waterstop. Pour the concrete to 1/2 or 1/3 of the width of the steel plate mastic waterstop. Before the second pouring, remove the upper protective film and then pour.

Precautions for butyl mastic steel plate waterstop

Before using butyl mastic steel plate waterstop, carefully read the product instructions and select the appropriate model and specifications according to the actual situation.

Construction should be carried out at appropriate temperature and humidity, avoiding large temperature differences and seasonal changes.

Before use, thoroughly clean the surface to ensure that the surface is smooth, clean, and free of any impurities and oil stains. Follow the correct usage method for construction, ensuring that each step is strictly operated to ensure quality and effect. During construction, pay attention to safety, use personal protection, and ensure that the product construction proceeds smoothly.

Transportation and storage of steel plate mastic waterstop

Care should be taken not to damage the protective film of the waterstop to avoid damaging the waterstop. Because the steel plate mastic waterstop has self-adhesive properties, during construction, care should be taken not to tear off the outer protective film of the steel plate mastic waterstop before the installation is completed.

Performance indicators of butyl steel plate mastic rubber waterstop:

| Item | Index |

| Density (g/m³ ) | 1.45+0.1 |

| Tensile strength (MPa) | 0.06 |

| Elongation at break | 1000 |

| High temperature fluidity (80℃×5h) | No flow |

| Low temperature test (-20℃×2h) | No cracking |

About Us

Hengshui Guangyuan Waterstop Materials Technology Co., Ltd. is a comprehensive enterprise that has been committed to the research, development, production, and sales of engineering waterstop rubber for nearly 30 years. It specializes in the research, development, production, and sales of professional sealing waterstop materials: water-swelling waterstop strips series, single/double-component polyurethane sealant series, steel plate putty waterstop series, rubber waterstop series, and caulking clay series products. The products are reliable in quality and widely used, and have been recognized by many engineering units!

Business Philosophy: Focus on building waterproofing: Providing high-quality products and services for building waterproofing

Service Concept: To make customers satisfied with comprehensive, meticulous, and efficient service

Business Spirit: Quality Assurance, Professional Service: Double guarantee to eliminate the worries of users about waterproofing

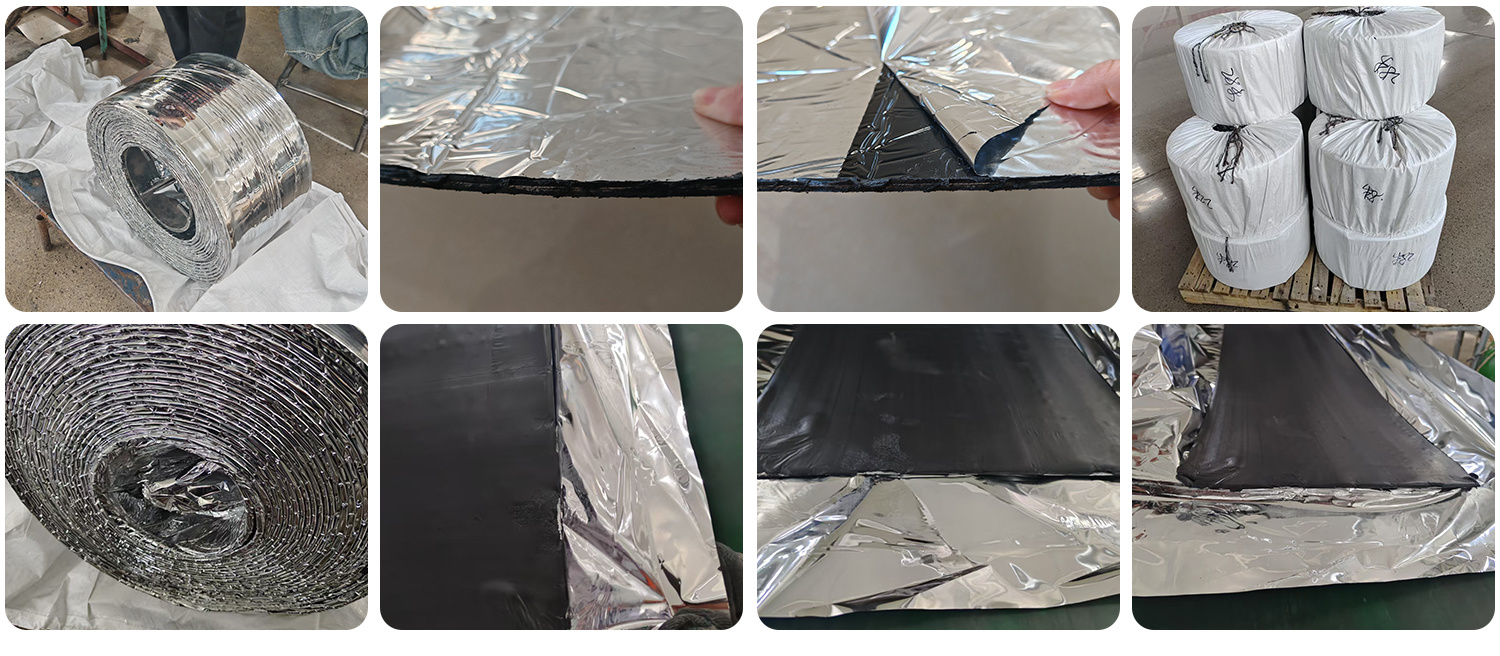

Production and Inspection

Factory Photos

Keywords

Free Access To More Product Information

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible!